Your Authorized Swagelok Sales and Service Center

Swagelok Georgia | Jacksonville | South Carolina is your local Sales and Service Center for Swagelok.

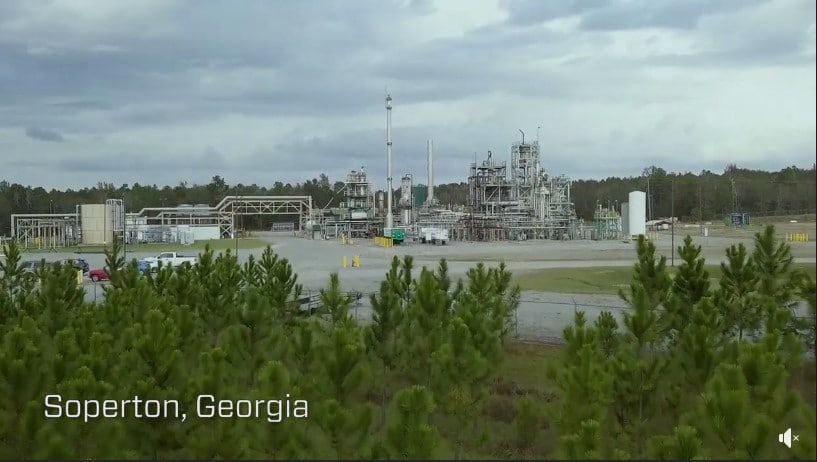

Swagelok Georgia | Jacksonville | South Carolina is dedicated to helping you keep your plant running at its most efficient state. We offer a variety of products and services designed to provide you and your team with the confidence of a safe and leak free plant. We are one of 225 sales and services centers representing Swagelok products. We provide products and services to meet the needs of individuals in Georgia, Northeast Florida, and South Carolina.

Quick Links

Featured Stories

Your Local Swagelok Sales and Service Center

Contact UsSwagelok Georgia

6815 Meadowridge Court

Alpharetta, Georgia 30005

678-624-0949

Swagelok Jacksonville

3500 Beachwood Court, Suite 208

Jacksonville, Florida 32224

904-642-2093

Swagelok South Carolina

2516 River Road

Piedmont, SC 29673

864-295-6700

For a location map and hours of operation

Service Area

Georgia, Northeastern Florida, and South Carolina