Swagelok® Fluid System Products — Components and Assemblies

We built our reputation on quality, and it remains one of our core values today. That’s why leak-tight Swagelok® fluid system components and engineered assemblies are trusted to reliably contain, control, and transfer liquids and gases around the world.

Explore All ProductsSwagelok products deliver the reliability, ease of installation, and lasting performance needed to keep processes and equipment operating safely, efficiently, and cost effectively.

- Swagelok® fittings have provided leak-tight connections between components in industrial fluid systems since 1947

- Swagelok® valves dependably control flow across a broad range of working pressures, temperatures, and operating conditions

- Swagelok® pressure regulators consistently and accurately maintain pressure levels over extended operating lifespans

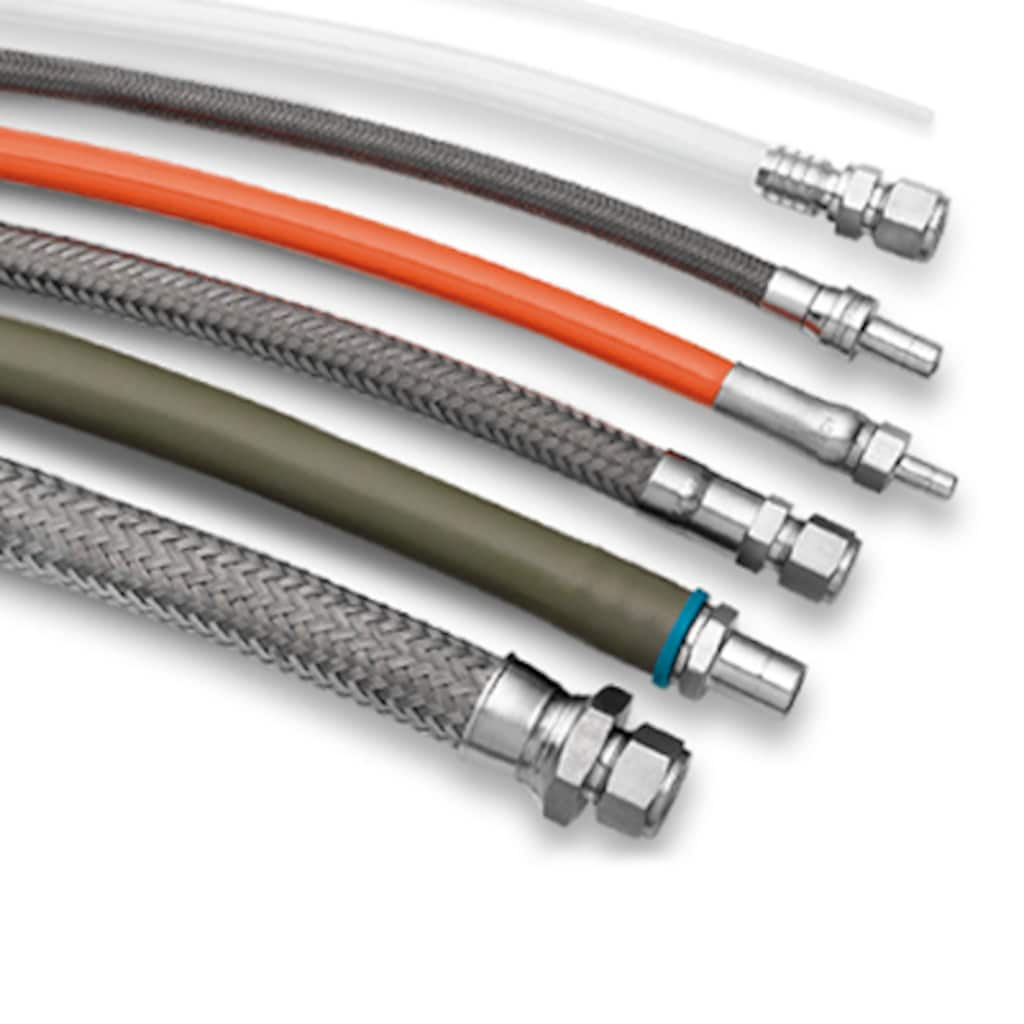

- Swagelok® hoses are available in a variety of materials, pressure ratings, and degrees of flexibility for industrial applications

- Swagelok® fluid system assemblies are designed, built, and tested by highly trained engineers and technicians

Need help with product selection? Check out the resources in our Product Selection Toolbox, or contact your local authorized Swagelok sales and service center for direct assistance.

To view pricing information, be sure you have registered and are logged in.

Categories

Fittings

Fittings

- Tube Fittings and Adapters

- Assembly-by-Torque Fittings (AbT)

- Cone and Thread Fittings

- Dielectric Fittings

- Flange Adapters

Valves

Valves

- Atomic Layer Deposition (ALD) Valves

- Ball and Quarter-Turn Plug Valves

- Bellows-Sealed Valves

- Check Valves

- Diaphragm-Sealed Valves

Regulators

Regulators

- Back-Pressure Regulators, Dome-Loaded

- Back-Pressure Regulators, Spring-Loaded

- High-Purity, High-Flow Gas Regulators, HF Series

- Pressure-Reducing Regulators, Dome-Loaded

- Pressure-Reducing Regulators, Spring-Loaded

Reliable Fluid System Components Assembled into Custom Subsystems

Receive dependable fluid system assemblies that are fully built and configured to your requirements, then tested by Swagelok-trained specialists.

Find Fabrication SupportSwagelok Resources Curated for You

Common Causes and Costs of Fluid System Leaks

The smallest leak can present a serious issue when maintaining your plant’s safety and profitability. Understand how and why leaks occur, how to locate and test for them, and how to address and reduce leaks plant-wide.

How to Improve Fluid System Performance

Learn about the importance of creating a learning culture that focuses on continuous system improvement, minimizing installation errors, and equipping employees with the skills to tackle jobs with confidence.

Materials Matter: Selecting the Right Material for Corrosion Resistance

There are numerous aspects to consider when specifying materials to help manage corrosion. Many considerations go beyond the material itself. Learn what it takes to build systems that will last.

Maximizing the Life of Industrial Fluid System Components

The cost of replacing an industrial fluid system component goes beyond the price of the part. Learn how to lower system costs while maximizing the life of your components with preventive maintenance.

Reliable Swagelok Fluid System Components and Assemblies

We apply expertise in product design, materials science, and manufacturing to supply a broad portfolio of high-quality fluid system products used in fluid system applications in diverse industries around the world. These include fittings, valves, pressure regulators, hoses, rigid and flexible tubing, tube accessories, gauges and other measurement devices, filters, welding systems, leak detectors, lubricants, sealants, and quick connects. We also design and fabricate fluid system assemblies including grab sampling, gas distribution, mechanical seal support, analytical subsystems, and miniature modular systems.

Our products are designed to stand up to the demands of challenging operating environments in diverse industries across the globe, are thoroughly tested, and are backed by the Swagelok Limited Lifetime Warranty.